Applications Advanced actuators using SILA technology are in development for break-through solutions in Aerospace and Bionic Prosthetics. With technology and manufacturing readiness increasing rapidly, WaveDrives is exploring robotic, industrial and energy capture applications for more direct, less regulated routes to market.

Applications

Advanced actuators using SILA technology are in development for break-through solutions in Aerospace and Bionic Prosthetics. With technology and manufacturing readiness increasing rapidly, WaveDrives is exploring robotic, industrial and energy capture applications for more direct, less regulated routes to market.

In preparation, WaveDrives worked with the National Physical Laboratory to develop scaling models optimising power-to-weight for SILA’s unique magnetic arrays. WaveDrives then designed and built SILA-P8 to an Airbus specification for utility actuation.

Evolution of SILA for landing gear application prepares for wider electrification applications in aerospace, marine, automotive and industrial.

Aerospace electrification

Driven by climate change imperatives, aerospace is developing more/hybrid/all electric aircraft for lower fuel consumption, fewer emissions and lower total cost. Actuators used in safety critical systems need to be non-jamming with no single point failure modes. SILA actuators are being evaluated for next generation aircraft landing gear, as part of Airbus’ LANDOne project within the Air Technology Institute’s Strategic Program.

In preparation, WaveDrives worked with the National Physical Laboratory to develop scaling models optimising power-to-weight for SILA’s unique magnetic arrays. WaveDrives then designed and built SILA-P8 to an Airbus specification for utility actuation.

Evolution of SILA for landing gear application prepares for wider electrification applications in aerospace, marine, automotive and industrial.

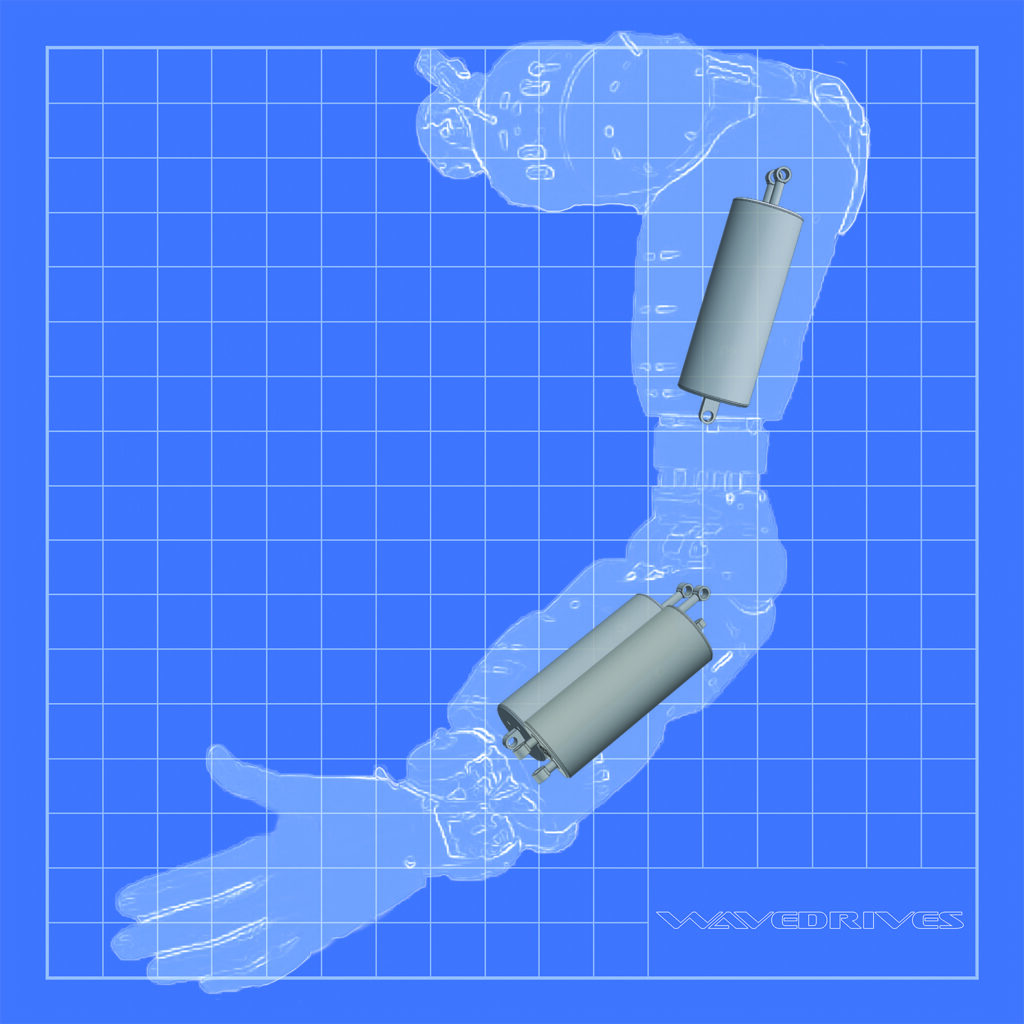

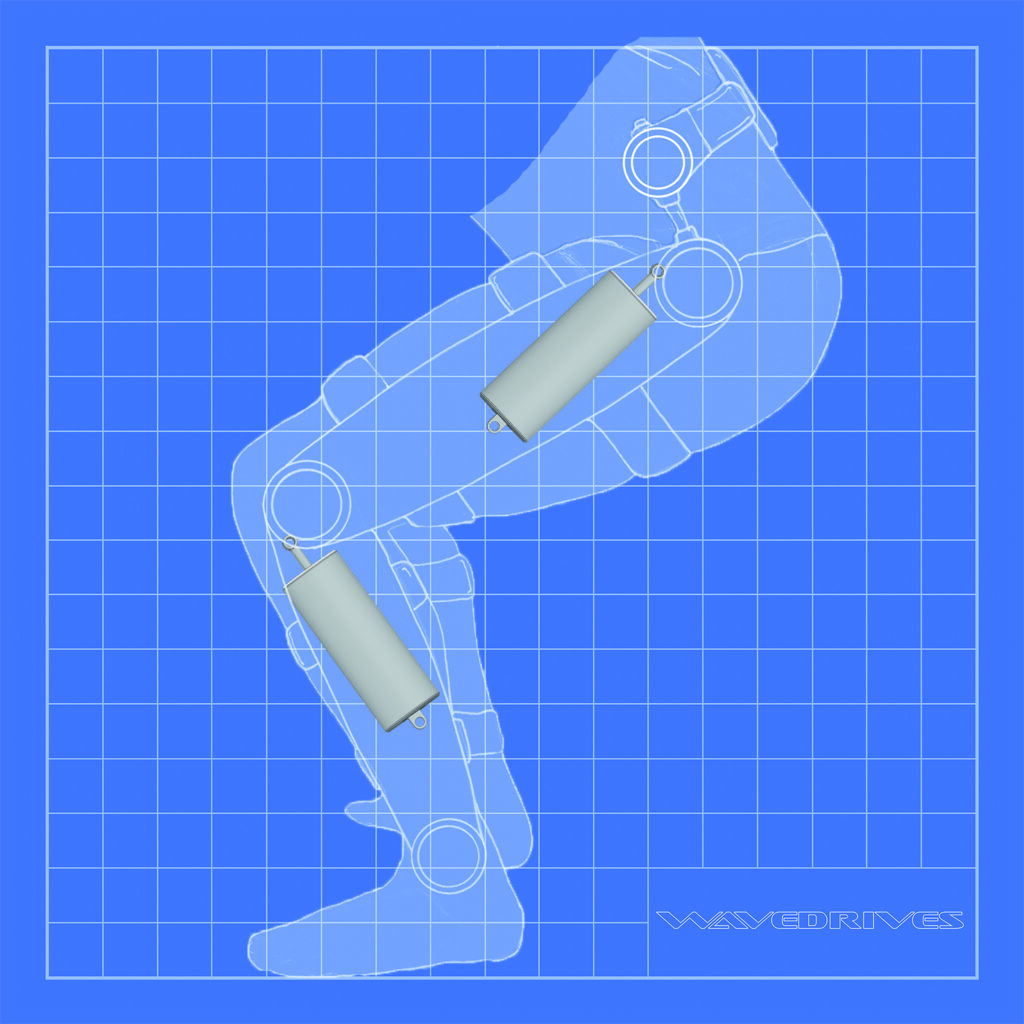

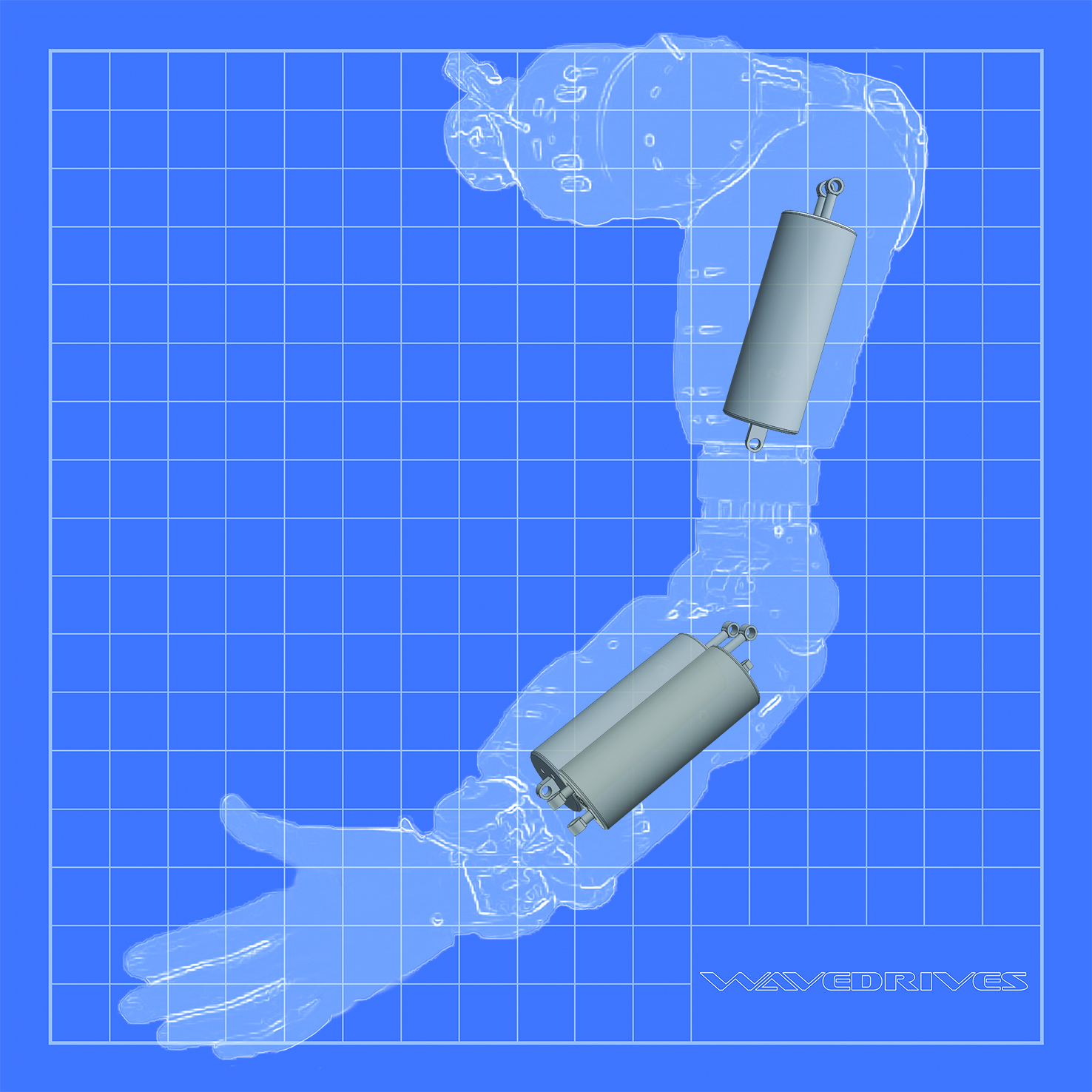

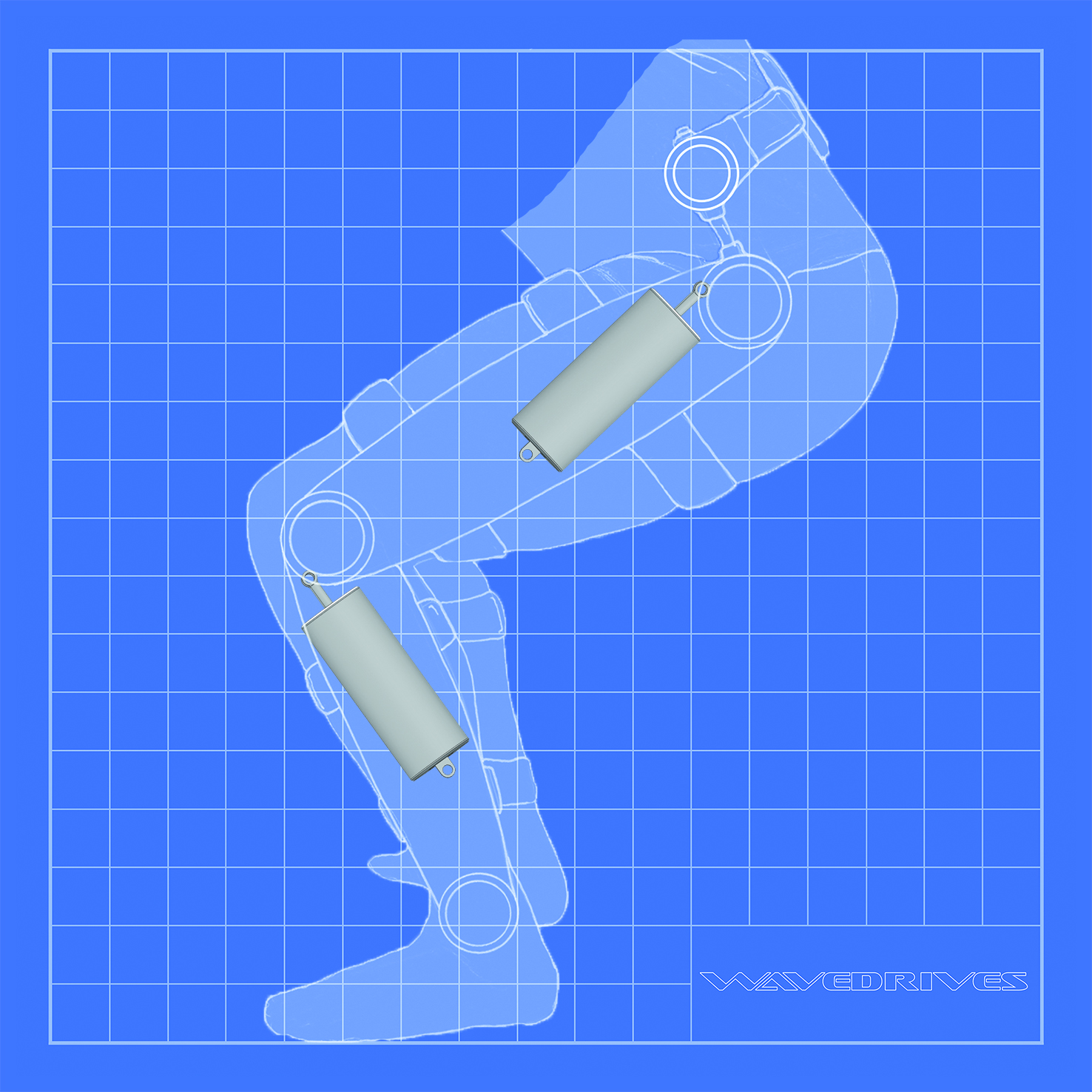

Bionic prosthetics present a huge actuation challenge. A prosthetic needs to match the missing limb, not just in appearance but in use.

Form, function, safety, reliability, availability, acceptability and lifetime cost-of ownership are key to meeting end-user needs.

Ossur, the market leading bionics supplier, has selected SILA for its development program. Bionic applications are expected to make full use of SILA features for OEM, end-user and service chain benefit. Evolution of SILA for prosthetic applications prepares for wider applications in humanoid robotics, exoskeletons and rehabilitation.

Bionic prosthetics

This area presents a huge actuation challenge. A prosthetic needs to match the missing limb, not just in appearance but in use.

Form, function, safety, reliability, availability, acceptability and lifetime cost-of ownership are key to meeting end-user needs.

Ossur, the market leading bionics supplier, has selected SILA for its development program. Bionic applications are expected to make full use of SILA features for OEM, end-user and service chain benefit. Evolution of SILA for prosthetic applications prepares for wider applications in humanoid robotics, exoskeletons and rehabilitation.

Industrial Safer co-bots; more cost-effective pick & place; process control with real-time force sensing and warehouse vehicles with longer duty cycles are all possible with SILA efficiency and feature-set. Once in mass manufacture, low lifetime cost of ownership, low downtime and ease of retro-fit could make SILA a highly competitive alternative in industrial applications currently served by conventional linear actuation.

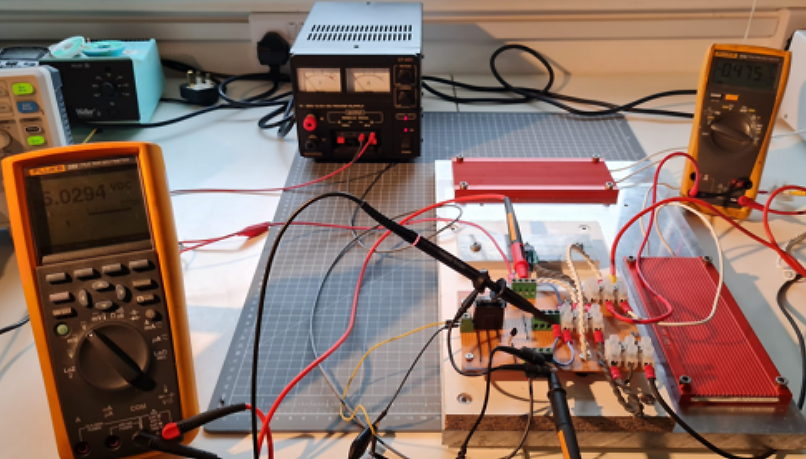

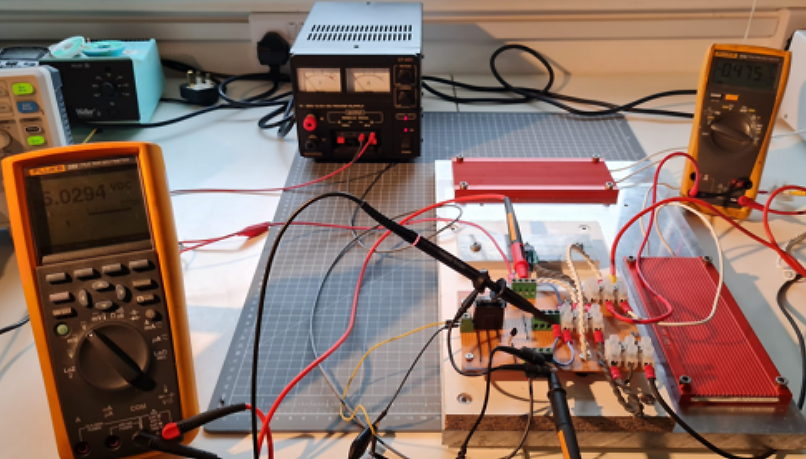

Energy capture SILA offers efficient electricity generation using wave or braking energy due to its ultra-efficiency/low backdrive force requirements and predictable backdrive. The red braking resistors in this test setup were needed to store the power generated in a SILA-P8 backdrive test. Wave profile devices are of particular interest as are many forms of active suspension. With no wear and no polluting lubricants or coolants, SILA is well suited for use in sensitive marine environments. Once in mass manufacture, low lifetime cost of ownership, low downtime and ease of retro-fit could make SILA a highly competitive alternative in industrial applications currently served by conventional linear actuation.

Industrial

Safer co-bots; more cost-effective pick & place; process control with real-time force sensing and warehouse vehicles with longer duty cycles are all possible with SILA efficiency and feature-set. Once in mass manufacture, low lifetime cost of ownership, low downtime and ease of retro-fit could make SILA a highly competitive alternative in industrial applications currently served by conventional linear actuation.

Humanoid robotics and exoskeletons

Human-scale collaborative robots use electro-mechanical actuation technologies for motion control, widely available and convenient but ultimately limited by friction and power-density. These limitations mean that these actuators fail to deliver reliable motion control across the wide dynamic range needed for safe robot-human interaction. The dominant use of rotary harmonic drives is also problematic in that wiring pathways through joints are significantly constrained. SILA technology addresses these issues and more and is particularly suited to introduction of AI motor control.

Energy capture

SILA offers efficient electricity generation using wave or braking energy due to its ultra-efficiency/low backdrive force requirements and predictable backdrive. The red braking resistors in this test setup were needed to store the power generated in a SILA-P8 backdrive test. Wave profile devices are of particular interest as are many forms of active suspension. With no wear and no polluting lubricants or coolants, SILA is well suited for use in sensitive marine environments. Once in mass manufacture, low lifetime cost of ownership, low downtime and ease of retro-fit could make SILA a highly competitive alternative in industrial applications currently served by conventional linear actuation.