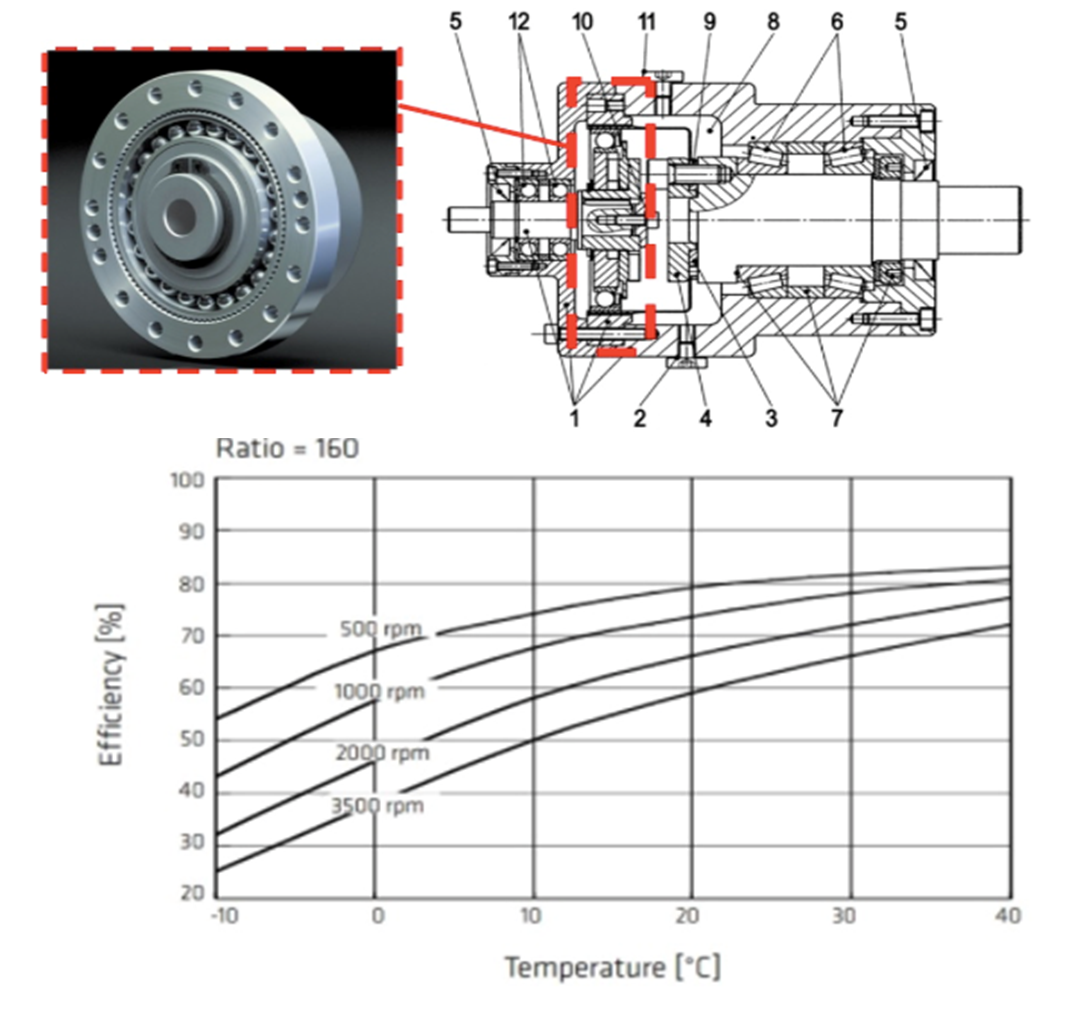

Harmonic drives combined with conventional electric motors are the go-to solution for robot joints but limit efficiency and power density and add weight and cost. Enduring flexispline elasticity is required, suggesting a super-stressed component. Lubricants further reduce efficiency. Although the harmonic drive gearing system is presented as a very compact solution in practice, to isolate all forces other than torsional and for the gear to work properly there are many accessory bearings. The graph shows how efficiency is adversely affected by temperature in the grease-filled drive. The efficiency of the drive is also adversely affected by torque load, but this is not easily illustrated.