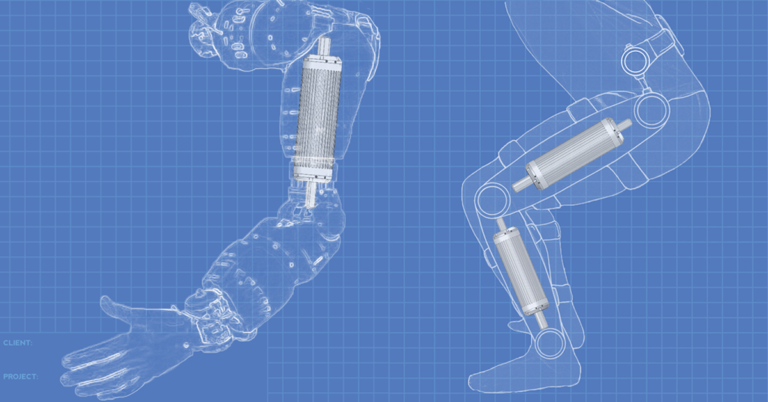

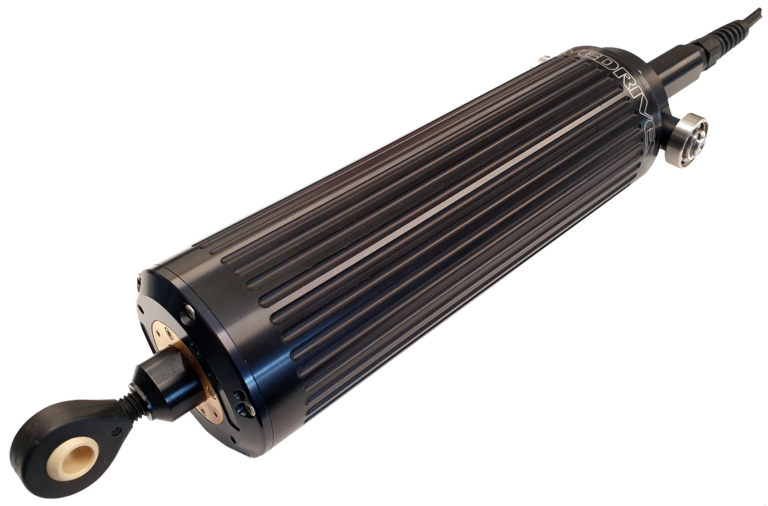

It looks like they’re using brushless dc motors to turn planetary satellite rollerscrews for their linear actuators. They say they can lift a grand piano … The average vertical or upright piano can weigh anywhere from 200-1000 lbs (91-545 kg). The average baby grand piano can weigh anywhere from 500-600 lbs (227-272 kg). The average professional grand piano can weigh around 700 lbs (317 kg), and a concert grand piano can weigh up to 1200 lbs (544 kg).

SILA P9 can do a baby grand … but it’s not all about force.

Planetary rollerscrews will definitely thrust loads of the grand piano order. We’ve talked about their downsides before. The chief one is that lubrication is critical for their performance, and really an oil bath of oil. In the robot, for practical reasons, it has to be grease lubrication and maintaining that grease lubrication will be Tesla’s challenge to solve. For example, if the threaded shaft of the roller screw increasing in temperature >80degC the case hardening starts being a problem with the through-hardened satellite rollers. Additionally, if the rollerscrew is rotated at very high rpm’s there are significant resonance issues. So, if they’ve got this high gearing for ‘grand piano’ levels of thrust they’ll be having to spin the rollerscrew at terrifically high rpm’s. Again, not good for longevity.